Flexibility comes as a standard

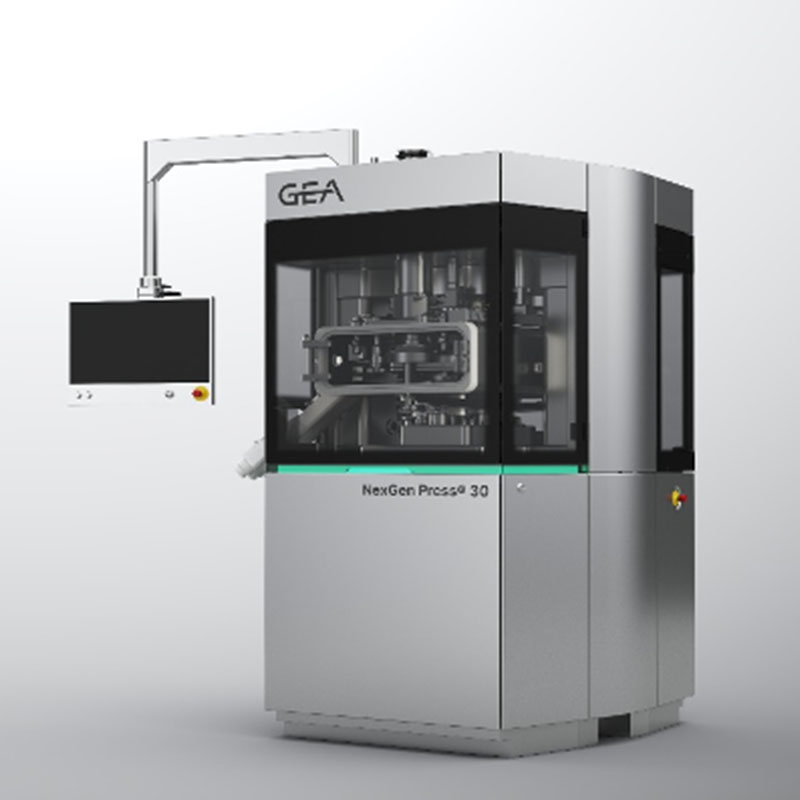

Available in two formats the CE-certified NexGen Press® GMP features a dust-tight enclosure for easy handling. If required, with the addition of lay flats and pressure monitoring, the GMP option can be upgraded for OEB 3 containment applications.

For example, an entry level machine can be upgraded to meet specific process requirements, such as bilayer tableting, different washing options and/or to further reduce the risk of cross-contamination, as and when required.

The NexGen Press® OEB offers both OEB 4 and 5 containment functionality and can be equipped with the BUCK® Digital Canary for real-time monitoring and/or the BUCK® (U)MC valve for contained loading.

Featuring a reduced-volume and isolated product contact area, the “double barrier” will increase operator safety. Being easier and faster to clean will mean shorter production changeovers and less downtime. The contained turret allows for a replacement to be installed in less than 1 hour. And, in an increasingly connected working environment, the presses are Industry 4.0-compatible and digitalized.

Designed to accommodate a wide range of functionalities, from general GMP production to high-containment applications, GEA has once again applied its experience and knowledge to serve the current and future pharmaceutical workforce, and the patients who depend on their products.

Furthermore, the NexGen Press® range is fully compatible with GEA’s new Digital Canary monitoring system, which both detects product leaks from contained pharmaceutical production lines and protects the health and safety of your operators.

Offering a number of plug-and-play options for applications including orodispersible, MUPS and bilayer tablets, the NexGen Press® also benefits from a user-friendly HMI with multitouch functionality, interactive digital manuals and online project documents.

A perfect blend of physical and digital

The patented Exchangeable Compression Module (ECM) concept not only provides improved containment and has a lower product-contact area compared with other models on the market, it is also WIP/WOL-compatible and facilitates fast changeovers in a small footprint, high-output rotary tablet press with multiple compression modes.

Modular by design, every NexGen Press® can be customized to fit specific applications — for now or the future — with predefined option packs. Examples include bilayer and MUPS tablets, poorly flowing powders, small volume/high yield products and those that require antisticking solutions.

Additional features such as punch face lubrication (iSpray), an intermittent cleaning system, A2D tooling for increased capacity, PAT integration and UL certification are also available.

For ongoing peace of mind, out-of-the-box training and support is always on hand. GEA offers immersive tuition via virtual reality, support intervention via a two-way remote Eyewear link, built-in preventive maintenance and a QR code system for spare parts.